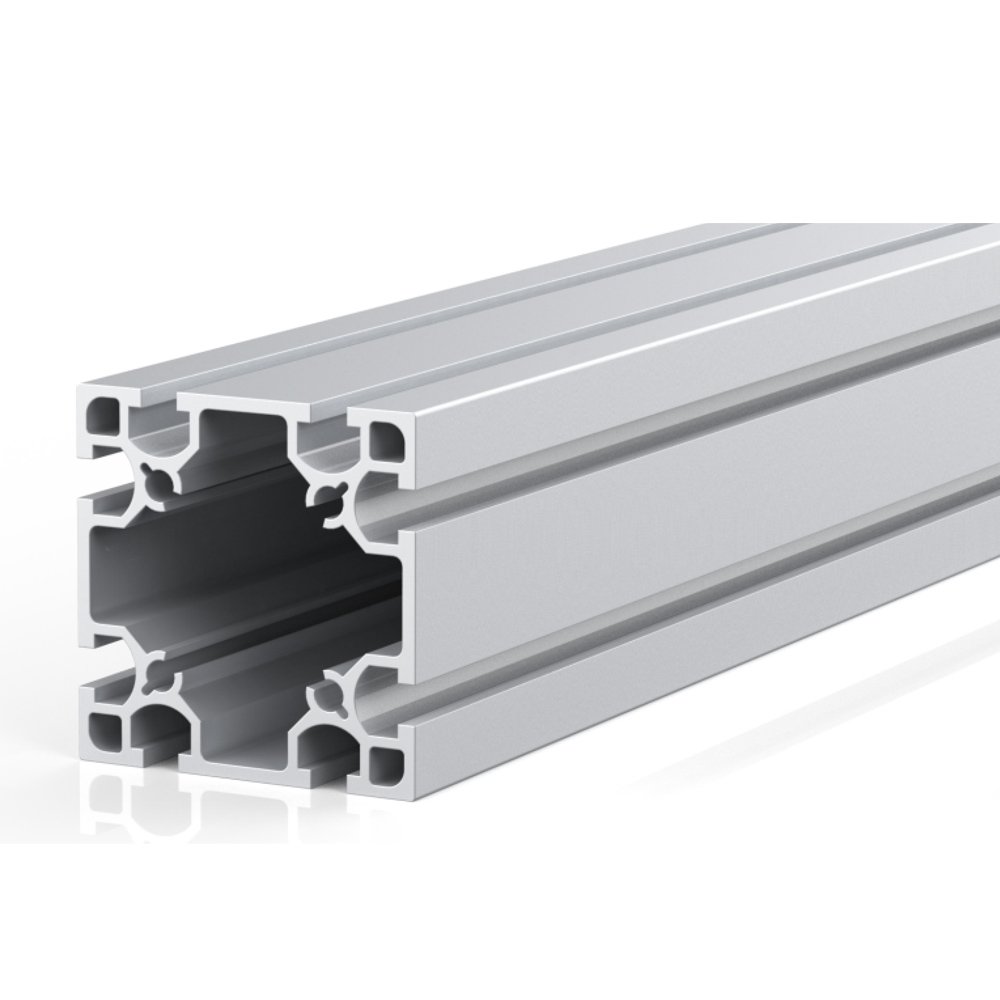

Aluminum material for Industry Automation

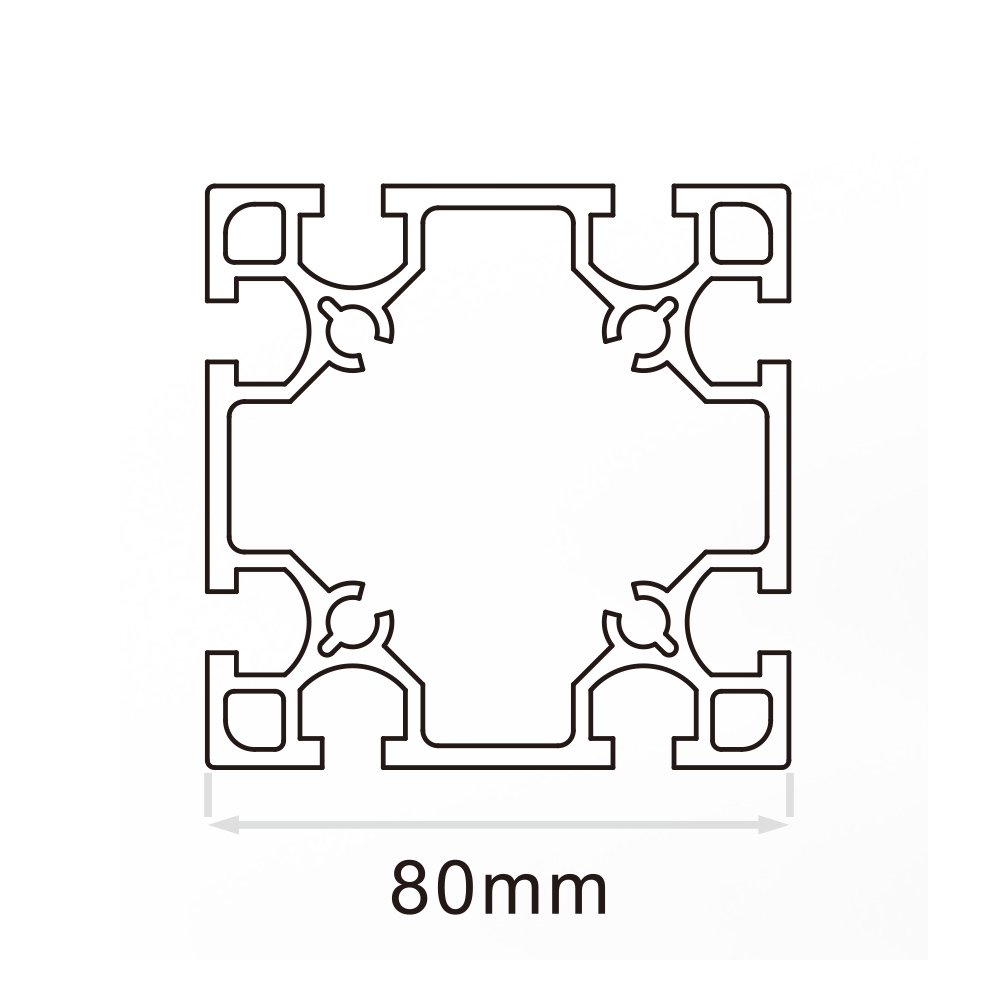

By optimizing die design, reducing pressure and accelerating speed, Rhine could meet the production requirements of various multi-cavity, thin-wall thickness and high-strength assembly line profiles.

Through majorizing alloy ratio, profiles produced by Rhine has higher strength and superior surface treatment performance. The tensile performance of the conventional 6063 assembly line profile can reach 260Mpa, far exceeding the national standard and peer level.

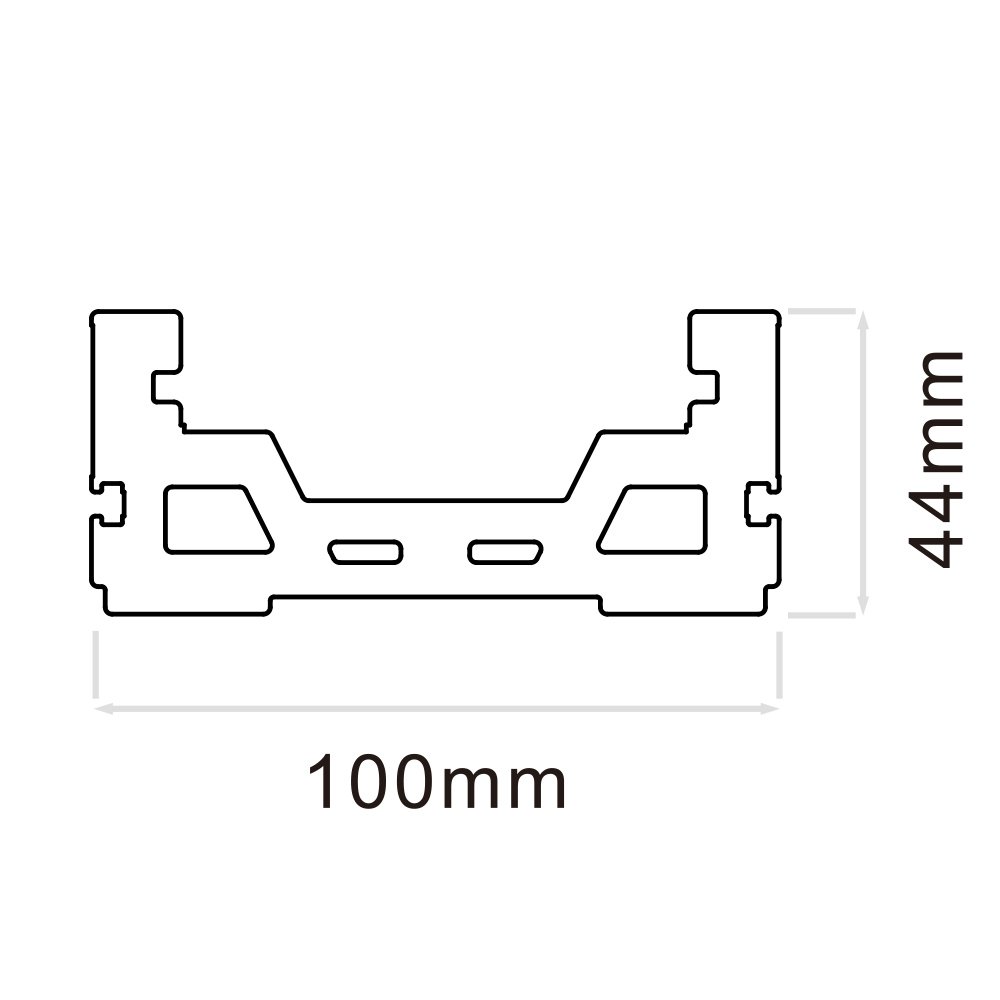

The highest flatness of the guide rail profile with complex structure can reach 0.5mm/2m through the mold secondary welding and sinking bridge process, with advanced tensile straightening technology, which also can shorten the cutting process, and reduce the material cost greatly.